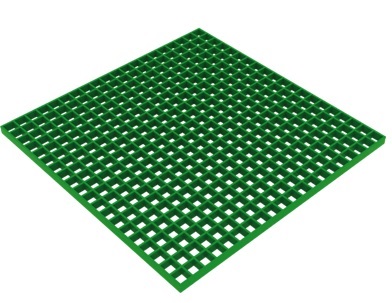

CPC is among leading FRP/GRP Moulded Gratings Manufacturers in India for their high strange, corrosion resistance, long life and safety.

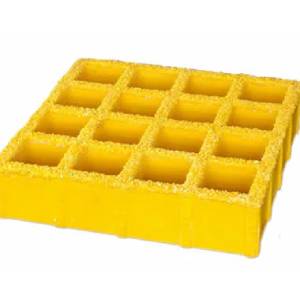

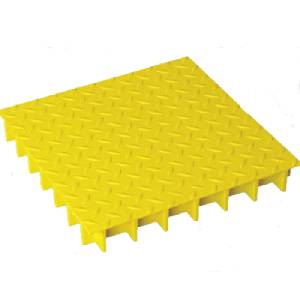

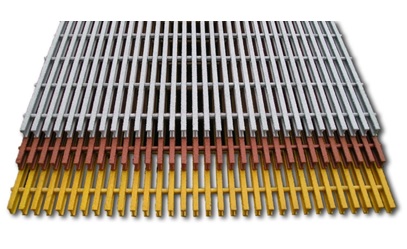

FRP moulded gratings are available in a variety of resins system, standard and custom colors, depths, panel sizes and mesh configurations. Top surface option including meniscus, anti skid, chequered plate.FRP Moulded Grating is used in place of traditional materials for a FRP solution that fit a wide range of application and environments.

Types of Surface :

| Description | CPC FRP Gratings | HOT DIP GI | Stainless Steel |

|---|---|---|---|

| Cost of Life Cycle | Low | High | High |

| Life Span | High | Average | High |

| Ratio of Strength to Weight | High | Low | Low |

| Resistivity of Corrosion | Very High | Average | High |

| Resistivity of Chemical | High | Average | High |

| UV Protection | High | Average | High |

| Installation Cost | Low | Average | Average |

| Hanling | Very Easy | Difficult | Difficult |

| Anti Slip | Available | N/A | N/A |

| Colour | Customise | N/A | N/A |

| Resin Type | Resin Base | Description |

|---|---|---|

| Type I | Isoththalic Polyester | Industrial Grade Corrosion resistance in acidic environment |

| Typ I-FR | Isoththalic Polyester Fire Retardant | Industrial Grade Corrosion resistance & fire retardant |

| Type V | Vinyl Ester | Superior Corrosion resistance |

| Type V-FR | Vinyl Ester Fire Retardant | Superior Corrosion resistance & fire retardant |

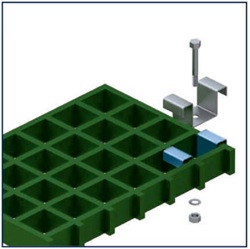

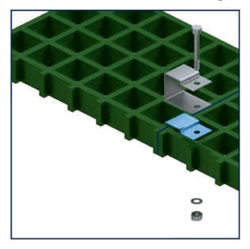

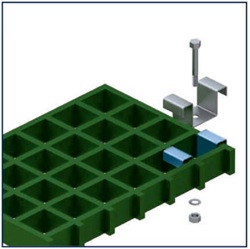

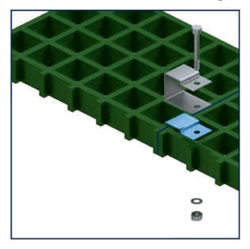

Accessories are very important part of fixing and quick installation of grating. we design different types of clamp to used depends upon the application of end user.

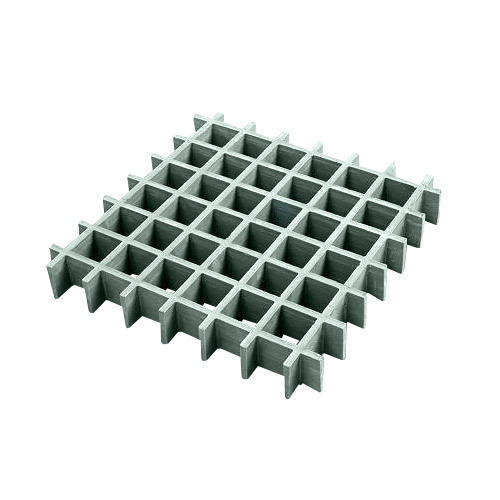

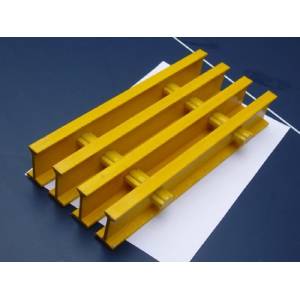

CPC FRP/GRP Pultruded grating offers a fast, safe and effective flooring solution to high load carrying capacity areas. Pultruded grating is manufactured by pulling glass-fiber reinforcement through a thermosetting polyester or isophthalic or vinylester resin bath. The thoroughly wetted-out fibers are then fed through a heated steel die to achieve the shape of the tool.

There are generally two components to a pultruded grating, 1) the Load Bearing Bar and 2) the Tie or Cross Bars. These are cross bars are generally from two different shapes to ensure an interlocking mechanism can be achieved.

The Load bearing bars are drilled at approx. every 100 to 150mm centers to accommodate the interlocking cross bars. The cross bars are then fed through the load bars in a jig and bonded together to make the finished panel of grating.

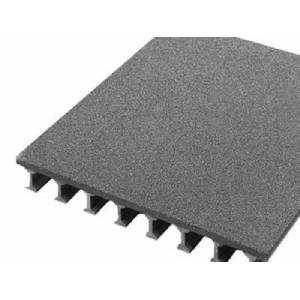

Types of Top Surface :

| Description | CPC FRP Gratings | HOT DIP GI | Stainless Steel |

|---|---|---|---|

| Cost of Life Cycle | Low | High | High |

| Life Span | High | Average | High |

| Ratio of Strength to Weight | High | Low | Low |

| Resistivity of Corrosion | Very High | Average | High |

| Resistivity of Chemical | High | Average | High |

| UV Protection | High | Average | High |

| Installation Cost | Low | Average | Average |

| Hanling | Very Easy | Difficult | Difficult |

| Anti Slip | Available | N/A | N/A |

| Colour | Customise | N/A | N/A |

| Resin Type | Resin Base | Description |

|---|---|---|

| Type I | Isoththalic Polyester | Industrial Grade Corrosion resistance in acidic environment |

| Typ I-FR | Isoththalic Polyester Fire Retardant | Industrial Grade Corrosion resistance & fire retardant |

| Type V | Vinyl Ester | Superior Corrosion resistance |

| Type V-FR | Vinyl Ester Fire Retardant | Superior Corrosion resistance & fire retardant |

Accessories are very important part of fixing and quick installation of grating.we design different types of clamp to used depends upon the application of end user.